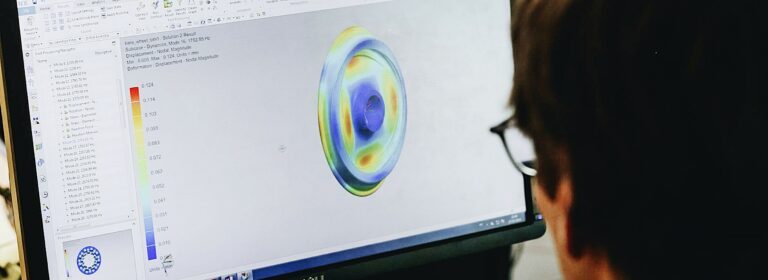

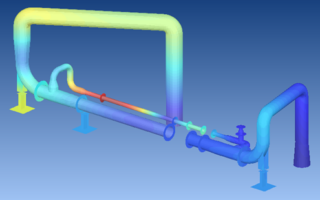

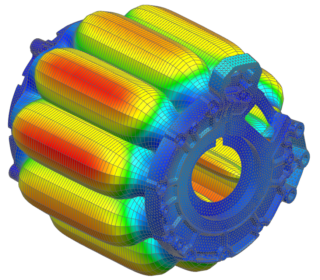

Vibratec specializes in providing advanced computational services that enhance the design, performance, and reliability of products across various industries such as aerospace, automotive, energy, and defense. Using state-of-the-art numerical simulations, Vibratec offers a wide range of services that target crucial aspects of product optimization.

By combining these advanced simulation techniques, Vibratec helps clients predict the performance of their products under real-world conditions, reduce the need for extensive physical testing, and optimize overall design and efficiency.