Vibratec provides a comprehensive range of instrumentation and diagnostics services tailored to measure, analyze, and optimize the physical performance of systems under real-world conditions. Here is a more detailed overview of their key offerings and the benefits they bring to various industries.

Instrumentation

Why Vibratec’s Instrumentation and Diagnostic Services Matter

01

Early Detection and Prevention

Identifying issues such as vibrations, noise pollution, or material deformation early in the design process prevents costly failures and reduces maintenance costs.

02

Optimized Performance

Precise measurements and analysis allow for product designs to be optimized for efficiency, safety, and longevity, whether it’s a rotating turbine, a building, or a high-performance vehicle.

03

Compliance and Safety

Many industries, including aerospace, automotive, and civil engineering, must comply with stringent safety and performance regulations. Vibratec’s diagnostics ensure that products meet all required standards, minimizing the risk of regulatory non-compliance.

04

Enhanced Innovation

By simulating and testing products in controlled environments, Vibratec helps companies innovate with greater confidence, ensuring that new designs perform as expected under a variety of conditions.

Vibration Analysis

Vibration analysis is critical for detecting early signs of mechanical failure in rotating or stationary equipment. Vibrations can often indicate misalignment, imbalance, looseness, or wear in machinery, and their detection allows engineers to address these issues before they escalate. Vibratec uses high-precision sensors and diagnostics to analyze the vibrational behavior of machines and structures.

This service is particularly beneficial in industries where continuous operation and high mechanical loads are common, such as manufacturing, automotive, and energy. For example, detecting vibrations in rotating machinery like turbines, engines, or compressors allows for predictive maintenance, minimizing unplanned downtime, extending machinery life, and reducing operational costs. In this way, Vibratec helps ensure that critical systems remain operational and safe.

Acoustic Analysis

Vibratec’s acoustic analysis service helps industries manage and reduce noise pollution, which is often a regulatory and operational concern. Acoustic diagnostics involve measuring noise levels and identifying noise sources within mechanical or structural systems. Vibratec offers targeted solutions to mitigate excessive noise, improve sound quality, and optimize product design.

Acoustic performance is a key concern for industries like automotive, aerospace, and urban development, where reducing noise pollution not only meets legal standards but also enhances user comfort and public safety. In automotive design, for instance, acoustic analysis can help reduce cabin noise from engines or external sources, leading to improved user experience and competitive advantages in vehicle quality.

Acyclism Measurements

Acyclism refers to variations in rotational speeds and uneven motion in mechanical systems, particularly in rotating equipment. Vibratec specializes in measuring and analyzing acyclism, which is crucial for the stability and longevity of rotating machinery such as motors, turbines, pumps, or fans.

Acyclism can lead to uneven wear, increased vibration, and mechanical stress, potentially shortening the equipment’s lifespan. By using precise diagnostic tools to monitor and adjust the performance of rotating systems, Vibratec ensures that these systems function reliably even under varying operating conditions. This service is particularly important in energy, manufacturing, and transportation sectors where consistent mechanical performance is essential.

Dynamic Force Measurement

Dynamic force measurements are essential for understanding how mechanical systems handle operational loads, impacts, or fluctuating forces over time. Vibratec’s expertise in this area allows for accurate measurement of forces exerted on structural components or machinery in dynamic conditions, using both direct and indirect measurement techniques.

In industries like aerospace, automotive, and construction, understanding the dynamic forces at play is crucial for designing systems that can handle stress without compromising safety or performance. For instance, in aerospace applications, dynamic force measurements help design aircraft components that can withstand extreme aerodynamic forces during flight. In automotive engineering, this service ensures that vehicles can safely handle high-speed impacts and other stresses encountered on the road.

Deformation Measurements

Vibratec’s deformation measurement service assesses the material strain and deformation experienced by structures or components under stress. This type of measurement is critical in sectors where structural integrity and safety are non-negotiable, such as in civil engineering, aerospace, and energy.

By measuring deformation, Vibratec helps industries understand how materials will react to real-world conditions, such as thermal expansion, mechanical load, or environmental forces. For example, in civil engineering, deformation measurements are used to monitor the behavior of bridges, buildings, or other infrastructure under load, ensuring that these structures remain safe and functional over time.

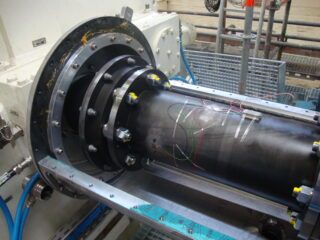

Test Benches

Vibratec’s test benches offer customized testing environments where components or full systems can be subjected to real-world conditions in a controlled setting. These benches are designed to simulate operational loads, vibrations, temperatures, and other environmental factors to verify product performance before deployment.

Test benches are particularly useful in R&D and quality assurance processes in industries like automotive, aerospace, and defense. For instance, a test bench might be used to evaluate the durability of a new engine design under varying temperatures and loads, or to simulate the operational conditions of a new turbine component. By providing highly controlled testing environments, Vibratec enables companies to validate their designs and ensure product reliability, durability, and safety before products are mass-produced or deployed in the field.

Vibratec’s instrumentation services offer a comprehensive approach to diagnostics and testing, combining real-time monitoring with precise measurements. This expertise is particularly valuable in industries such as aerospace, automotive, energy, and defense, where understanding the behavior of products under various operating conditions is essential. The ability to simulate, measure, and analyze physical phenomena ensures that products are optimized for performance, safety, and compliance with industry standards.

By leveraging their vast experience in diagnostics and measurement technology, Vibratec enables businesses to not only detect issues early but also to refine designs, ultimately reducing the risk of failure and costly downtime.

Instrumentation