At Vibratec Asia Pacific, we are proud of our tailored approach to vibration fatigue analysis, a methodology developed by Vibratec SAS. Our approach is designed to assess the remaining lifespan of rolling stock through a comprehensive examination of four critical milestones (Specification, Design, Fabrication, Operation).

Asset Management – Rolling Stock Life Extension

Context

Client Benefits

01

Asset Longevity

Determines the feasibility of extending the service life of rolling stock beyond its originally intended lifespan

02

Cost-efficiency

Allows operators to confirm that equipment can continue to operate safely and efficiently with minimal additional investment

03

Predictive Maintenance

Reduces maintenance costs by enabling predictive maintenance rather than reactive maintenance

Challenges

01

Perform precise fatigue analyses under various real-world conditions, leading to more reliable predictions of asset lifespan

02

Utilize existing data and models that may be applicable, to create tailored models for each unit and ensure accurate predictions of their remaining service life

03

Safety-first philosophy to ensure that service life extensions do not compromise safety while optimizing cost-efficiency for clients

Key Development Points and Approach

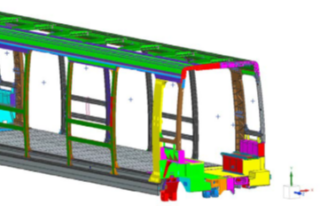

Rolling stock life extension evaluation is essential for maintaining operational efficiency and safety. Our advanced capabilities in 3D modelling and finite element analysis offer accurate assessments and targeted recommendations for extending service life. With its deep expertise in structural evaluation and monitoring, Vibratec is ideally positioned to support transit authorities in ensuring that their fleets remain reliable and cost-effective.

Our methodology includes

1. Design Review

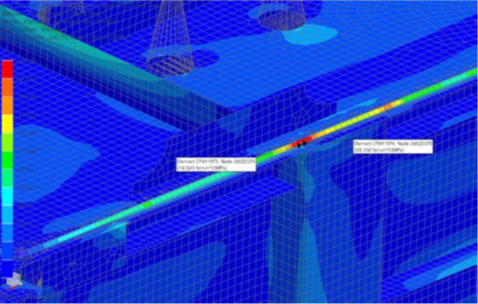

Evaluation of the body’s mechanical design by creating a finite element model and ensuring that the mechanical stresses under normative loading conditions remain below the materials’ fatigue limits. These loads account for the weight of passengers and the stress requirements defined by EN 12663 standards.

2. Structural Integrity Analysis

This phase involves conducting inspections on a body in the workshop to assess its mechanical integrity. Visual inspections and non-destructive testing (NDT) methods concentrate on areas identified as sensitive by Vibratec. The goal is to detect any cracks or defects that may have developed.

3. Determination of Actual Loading in Operation

This phase involves evaluating the actual operational changes through on-line tests where the instrumented train will run both empty and loaded, with loading and unloading. Tests will follow standard operating conditions, including speeds, stops, and braking scenarios.

4. Increased Lifespan Support

This phase focuses on supporting the client in extending the train bodies’ lifespan. It involves developing life scenarios based on load evolution hypotheses from actual measurements, defining a monitoring plan for maintenance and specific inspections in sensitive areas, and proposing reinforcements or analyzing failure scenarios.