Vibratec played a role in supporting the Royal Malaysian Navy’s RMN 15 to 5 transformation goals. Our involvement in the refit and repowering project was critical to ensuring that the vessels met the stringent requirements for stealth mode operations. This comprehensive project included on-site vibration and noise surveys. We helped improve the operational efficiency and stealth capabilities of the Navy’s fleet, enabling them to perform more effectively in various missions. Our expertise ensured that the vessels met the expected performance standards, demonstrating our commitment to excellence in defence applications.

Marine Refit Repowering

Context

Client Benefits

01

On-site surveys provided real-time data in actual operating conditions

02

Immediate detection of vibration and noise problems

03

Vessel conformity to relevant marine industry standards and regulations

Challenges

01

Vibratec’s personnel are trained to handle the complexities of marine conditions, ensuring reliable data and safeguarding equipment

02

Vibratec’s experience in managing complex logistics ensured that equipment and personnel were efficiently coordinated and deployed, minimizing logistical issues

03

Vibratec reduced the time required on-site with our streamlined and efficient survey techniques, lessening any potential disruptions to the vessel’s operations

Key Development Points and Approach

Visual Inspection for Early Problem Identification

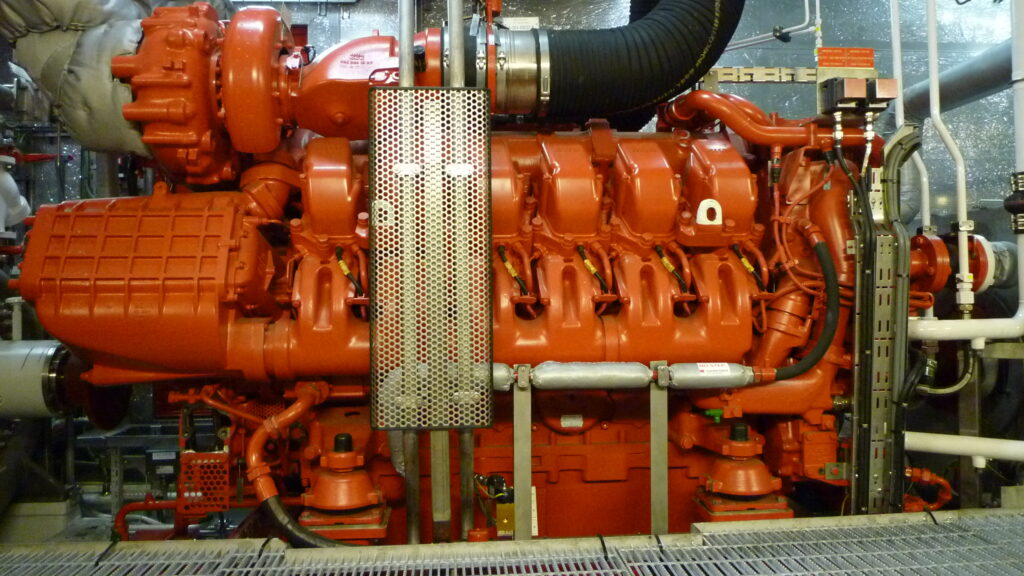

Our approach begins with a thorough visual inspection of the vessel’s machinery. This critical first step allows our experts to identify any visible abnormalities, such as wear, misalignments, or structural issues. By systematically examining each component, we lay the groundwork for targeted diagnostics, ensuring that no potential problem is overlooked. This proactive step helps us prioritize areas for detailed investigation, reducing downtime and enhancing operational efficiency.

Key Development Points and Approach

Comprehensive Measurement at Key Levels and Locations

Following the visual inspection, we conduct precise measurements across multiple levels and strategic locations on the machinery. Our team uses state-of-the-art sensors and monitoring equipment to collect real-time data under actual operating conditions. This approach enables us to capture critical insights into vibration and noise levels, providing a detailed understanding of the machine’s performance. By focusing on key areas, we ensure our analysis is both thorough and efficient, delivering actionable results.

Key Development Points and Approach

Detailed Inspection Report and Actionable Conclusions

After completing the inspections and measurements, we compile a detailed report outlining our findings, analyses, and recommendations. The report highlights specific issues, their root causes, and their potential impact on vessel performance. We provide clear, actionable conclusions, including tailored solutions to address the identified challenges. Our clients benefit from a comprehensive roadmap that not only resolves immediate concerns but also enhances the long-term reliability and efficiency of their vessels.